On May 22–23, 2025, at our headquarters in San Sperate (SU), Sardinia, we hosted the Orefice PowerDay: two days of meetings, demonstrations, and technical exchange, designed to put our clients and partners at the center and to share the values that guide us every day—innovation, expertise, and genuine relationships.

The Blackout of All Blackouts (until today) - July 13, 1977

Generator Sets in Urban and Environmental Projects: How to Frame Them and Why Choose an Ultra-Silent Model

Generator sets are an essential resource in numerous urban, industrial, and infrastructure projects. However, their use raises issues related to regulations, environmental impact, and urban planning. This article clarifies these topics, delving into regulatory guidelines and showcasing how Silengen generator sets are the ideal solution to address these challenges.

The relable solution to Sub-Zero applications: Discover Yeti Diesel Generators

How much does a generator set cost?

Better a Filter today than an Injector tomorrow. Do maintenance and save your generator!

What are the engine filters for?

Why do the engine filters get dirty?

A generator should be subject to regular and precise maintenance, based on the hours of operation and on the time elapsed since the previous maintenance.

Formerly we talked about how it is essential not to mix up with the maintenance of a generating set and the replacement of the filters only.

When we mention the filters, we usually refer to the most common ones, in fact the generator’s engine, usually has four types of filters:

1. Oil Filter

2. Oil Filter

3. Air filter

4. Water filter, also called separator filter

To these you can also add pre-filters that are installed depending on the case and the different applications.

Why is it so important to replace engine filters?

This question has an intuitive answer, in fact it is known that in general maintaining something preserves its functionality, therefore the maintenance of an engine, including the replacement of all filtering elements, serves to keep the engine running and therefore the whole machine.

What some users, and also some technicians, still fail to accept, is the need to perform maintenance of the generator installed for emergency service which is also called "stand-by": that type of generator that starts only in case of mains failure.

The commonplace is to check the number of total hours of operation and to assess based on whether the time has come to do maintenance.

The common place is to check the number of total hours of operation and to assess based on whether the time has come to do maintenance.

The generators in emergency service based on the hours totalled would not reach maintenance time even after 5 years, in fact it is rare to find an emergency generator that has worked for hundreds of hours!

Maintenance is to be carried out following the instructions of the manufacturer who usually prescribes the same at "n" hours of operation or every year, whichever comes first.

Why should the engine of a switched-off generator need to have filters and lubricating oil replaced?

To answer this question, let us take as an example the Human Body, an extraordinary machine that uses a very complex system of transporting oxygen and other vital elements to operate, such as "the blood".

When in carrying out its work, the Blood needs to be filtered, which is regularly done by the "Kidneys".

Do the kidneys stop working when we sleep? No.

Is there any reason why we can voluntarily afford the luxury of "deactivating" our kidneys? Not even for a dream, we know that it would lead to death in a short time.

Even the engine, whether it is diesel, petrol or gas, cannot work or simply be ready to run without a proper maintenance, even when it is "sleeping", that’s to say when it is off!

Even the best synthetic oil must be replaced. The engine lubricant does its job of adjusting the friction between the moving parts of the engine and preventing overheating of one or more parts. The functioning of the oil depends on its chemical properties, therefore an oil of a proven quality, which respects the specifications of the engine, can withstand maintenance intervals higher than a lower quality lubricant, but this does not drastically limit the need to replace it.

Paradoxically, a generator in an emergency network service may need to replace the engine oil in an equal way or even greater than that of a generator set in "prime" operation, that is, it works continuously.

The emergency generators are (depending on the application) equipped with an engine preheater. Preheater is installed on the coolant circuit or under the oil sump. In both cases the preheating systems keep the engine warm and ready to start in any season.

Pre-heating operation is regulated by a thermostat that activates and deactivates the system based on the temperature reached. The result is a continuous, albeit slight, thermal excursion of the oil which, being preheated, manages to maintain the optimum viscosity in the event of start-up. All this has a price from a technical point of view, that is the need to replace the lubricant regularly so that it does not lose its lubricating properties.

What about the fuel filter?

It is advisable to make a brief reference to the type of fuel that we take into consideration in this article: Diesel fuel for motor vehicles.

Gas oil is basically born as a resultant fuel during oil refining, so we can say that diesel is a refining by-product. Obviously today diesel is a much cleaner fuel than before, but still maintains high concentrations of impurities. Often the fuel is contaminated by the water that creeps into the storage tanks.

How the water get inside the tanks is not a mystery, but even worse the situation is aggravated by the microorganisms that are formed in the contaminated fuel.

Given that many injection pumps are naturally lubricated by the fuel itself, the only way to avoid damage to the injection system is the Filters.

So the diesel filter serves to prevent water, solids, and other substances from entering the injection pump and reaching the injectors.

The average value of a diesel filter is € 30!

The average value of an injector or pump ... Well, forget it!

Better a filter today than an injector tomorrow.What are the engine filters for?

• Why do the engine filters get dirty?

A generator should be subject to regular and precise maintenance, based on the hours of operation and on the time elapsed since the previous maintenance.

Formerly we talked about how it is essential not to mix up with the maintenance of a generating set and the replacement of the filters only.

When we mention the filters, we usually refer to the most common ones, in fact the generator’s engine, usually has four types of filters:

1. Oil Filter

2. Oil Filter

3. Air filter

4. Water filter, also called separator filter

To these you can also add pre-filters that are installed depending on the case and the different applications.

Why is it so important to replace engine filters?

This question has an intuitive answer, in fact it is known that in general maintaining something preserves its functionality, therefore the maintenance of an engine, including the replacement of all filtering elements, serves to keep the engine running and therefore the whole machine.

What some users, and also some technicians, still fail to accept, is the need to perform maintenance of the generator installed for emergency service which is also called "stand-by": that type of generator that starts only in case of mains failure.

The commonplace is to check the number of total hours of operation and to assess based on whether the time has come to do maintenance.

The common place is to check the number of total hours of operation and to assess based on whether the time has come to do maintenance.

The generators in emergency service based on the hours totalled would not reach maintenance time even after 5 years, in fact it is rare to find an emergency generator that has worked for hundreds of hours!

Maintenance is to be carried out following the instructions of the manufacturer who usually prescribes the same at "n" hours of operation or every year, whichever comes first.

Why should the engine of a switched-off generator need to have filters and lubricating oil replaced?

To answer this question, let us take as an example the Human Body, an extraordinary machine that uses a very complex system of transporting oxygen and other vital elements to operate, such as "the blood".

When in carrying out its work, the Blood needs to be filtered, which is regularly done by the "Kidneys".

Do the kidneys stop working when we sleep? No.

Is there any reason why we can voluntarily afford the luxury of "deactivating" our kidneys? Not even for a dream, we know that it would lead to death in a short time.

Even the engine, whether it is diesel, petrol or gas, cannot work or simply be ready to run without a proper maintenance, even when it is "sleeping", that’s to say when it is off!

Even the best synthetic oil must be replaced. The engine lubricant does its job of adjusting the friction between the moving parts of the engine and preventing overheating of one or more parts. The functioning of the oil depends on its chemical properties, therefore an oil of a proven quality, which respects the specifications of the engine, can withstand maintenance intervals higher than a lower quality lubricant, but this does not drastically limit the need to replace it.

Paradoxically, a generator in an emergency network service may need to replace the engine oil in an equal way or even greater than that of a generator set in "prime" operation, that is, it works continuously.

The emergency generators are (depending on the application) equipped with an engine preheater. Preheater is installed on the coolant circuit or under the oil sump. In both cases the preheating systems keep the engine warm and ready to start in any season.

Pre-heating operation is regulated by a thermostat that activates and deactivates the system based on the temperature reached. The result is a continuous, albeit slight, thermal excursion of the oil which, being preheated, manages to maintain the optimum viscosity in the event of start-up. All this has a price from a technical point of view, that is the need to replace the lubricant regularly so that it does not lose its lubricating properties.

What about the fuel filter?

It is advisable to make a brief reference to the type of fuel that we take into consideration in this article: Diesel fuel for motor vehicles.

Gas oil is basically born as a resultant fuel during oil refining, so we can say that diesel is a refining by-product. Obviously today diesel is a much cleaner fuel than before, but still maintains high concentrations of impurities. Often the fuel is contaminated by the water that creeps into the storage tanks.

How the water get inside the tanks is not a mystery, but even worse the situation is aggravated by the microorganisms that are formed in the contaminated fuel.

Given that many injection pumps are naturally lubricated by the fuel itself, the only way to avoid damage to the injection system is the Filters.

So the diesel filter serves to prevent water, solids, and other substances from entering the injection pump and reaching the injectors.

The average value of a diesel filter is € 30!

The average value of an injector or pump ... Well, forget it!

Better a filter today than an injector tomorrow.

Power Generators Maintenance

The generator set maintenance.

The generator set maintenance is often mistakenly exchanged with the engine service. It is true that engine service is one of the main activities of diesel generator maintenance. However, it should be noted that oil and filters’ replacement do not always correspond to true maintenance this being just one of the many activities that are part of "maintenance".

Obviously, a non-specialized workshop will have the interest to pass off as a checked generator that actually, after 5000 hours, it never had an insulation test.

Far be it for us to demonize the so much sold engine service but rather to highlight an indisputable fact, which is that a diesel generator maintenance is incomplete if you don’t know how to do it.

Do you have a trusted maintenance man? Is it the same maintenance technician who provides assistance on your electrical system, on the Boiler or even on your car? Don’t confuse friendship and business relationship.

Does your technician check the maintenance plan before working on your generator? At each hours intervals corresponds a type of maintenance, in particular for the generating sets in continuous operation. Have such intervals been respected.

If you’re an entrepreneur don’t forget that the generator is a machine and therefore it exposes your personnel at risks deriving from use. That’s why it is important that it should be always efficient and secure.

Should I do the service even if I didn’t use the generator?

If you do not use the generator, you still have to perform a maintenance every twelve months.

Like yoghurt, Lubricants and filter elements, as indicated by their respective manufacturers, have a deadline. even if you do not consume it at some point you have to throw it away

Lubricants loses its lubricating properties after a certain period of time and are unable to insure their performance.

If you are a skilled maintenance man, you should read the below article.

Diesel generating set maintenance: How to perform it by a professional

“We have a problem with the generator that does not start, Could you intervene please? It’s urgent”

“of course we can. Meanwhile, could I know when you have performed the last maintenance what were the last maintenance activities?”

“Maintenance has always been done but we don’t know when or exactly what was done. Oil and filters change for sure”

How many times have I had a similar dialogue with a new customer!

From now on, if you go on reading it means you are a professional, so perfectly aware of how a generator is composed and you know how insufficient the above mentioned activities and controls are, to confirm that the machine is functional and a full scale maintenance is performed. If instead you will stop here then you will continue to make a generic service engine convinced that this is the key element of the generator.

From where to start? From the start up.

Some may disagree on this first step but I like starting from the premise that the gens et must be working otherwise it is easy to run into the inconvenience of having performed all the maintenance and then to find out that due to an anomaly the generating set will not be in service.

Then after checking the coolant and engine oil levels, it is advisable to carry out a few minutes lasting commissioning ensuring that no anomalies are evident and there are no gross problems (e.g. engine fluid leaks). Only then the generator can be shut down in "OFF" position (if necessary disconnect the starter batteries) to proceed with the maintenance.

The best use and maintenance manuals don’t mention it but the best maintenance starts with a start-up test such as to establish that before the maintenance the generator was fully functional.

It is not difficult to imagine how difficult it can be to prove to complete maintenance that a defect was present even before our intervention

It’s not a stretch to imagine how difficult it can be to prove after maintenance is complete that a defect was present before our intervention.

In the next article we will talk about the engine.

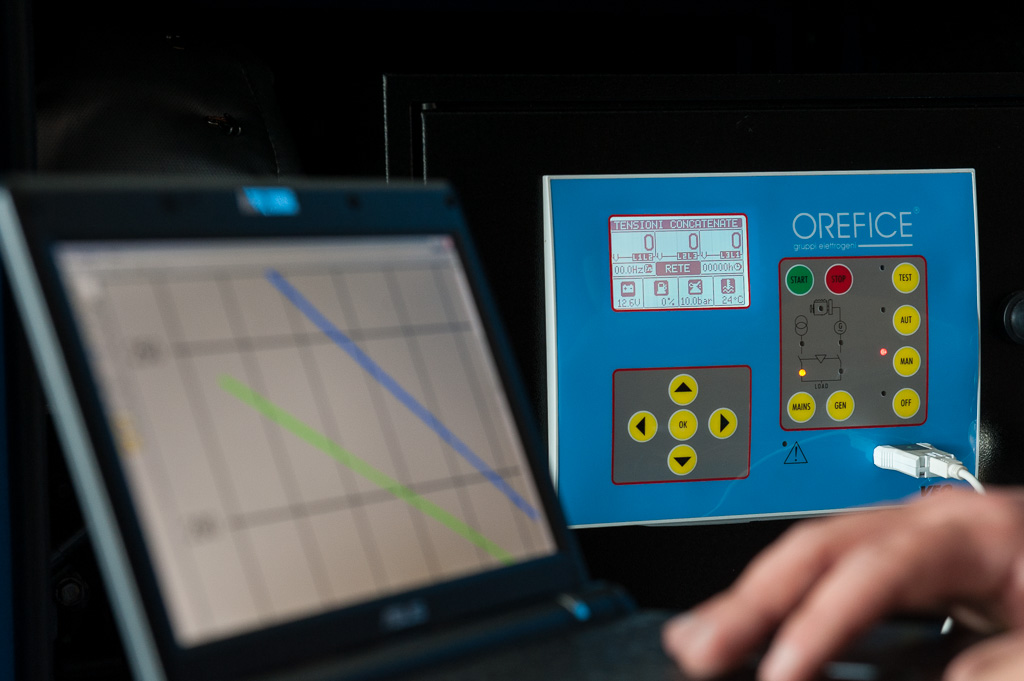

Case History: Power Generator under control with Remote Display.

If you have the right solution and technology, monitoring a generating set remotely is an easy task even without main.

Remote control of one or several devices is by now a common need for many applications although such need is not yet widespread when dealing with diesel generators.

One of our costumer who in Sweden deals with rental services for motion picture events decided to renew his generators fleet with our new Tesla generating sets taking advantage of the remote management of the generators.

His main problem consisted in not having the direct command of the generator from his workstation and consequently he had to dedicate an assistant just to monitor the generating set constantly.

Who’s working on audio services absolutely knows the problem: Supervising permanently the generator’s parameters and the fuel level is essential to avoid problems. Providing events’ services means to ensure a flawless work and not getting the generator under control is for sure a big mistake.

There’s a common concern in most remote control systems and it consists in the reliability of the system , often subject to local network’s configuration problems, Wi-Fi availability and even in the complexity of the system itself.

Our solution has been accepted by the customer since it seemed to be the most reliable one. We equipped the switchboard with a remote display panel connected to the VEO main controller of the generating set with a serial Port RS485.

Why RS485? The simplicity of the RS485 serial transmission make it the fastest and most trustworthy data transmission system. Indeed, within 10 metres distance it can reach a speed of 35Mpbs and it is also a cheap and easy to install system.

How does our remote display work?

It perfectly reproduces the generator’s display allowing to work as if the operator were in front of the generator. All the generator’s parameters and messages are shown simultaneously on both displays.

Why not a Wireless system?

Actually, in a context such as that of a motion picture event or any other commercial event where hundreds of electrical wires are lying on the floor, managing the generating set with a wireless system doesn’t make any sense. At least we believe it isn’t the best solution for our customer even if it would be more lucrative for us.

Watch the below Video...

BORN TO BE AUTOMATIC: WHEN THE DIESEL GENERATOR IS TRULY AUTOMATIC.

The automatic generator is a generator equipped with a Diesel engine that can boot up in the absence of electricity,

We specify "Diesel engine" since a gasoline engine generator can be automatic but it is extremely unreliable because the petrol engine does not have the same startup speed after long stop periods as automatic generator sets usually do.

Automatic generator is a generator that operates according to the following logic:

1. It should identify grid failures or anomalies in network parameters

2. Start and control the Diesel

3. Pilot the contactors or one or more motorized switches / circuit breakers for the connection of the load

4. Detecting the Return of the Network in the Parameter Triggers

5. Switching for network / network connection

6. Stop the Diesel

7. Return the position of the point 1 ready to repeat the cycle whenever it becomes necessary.

The above descrition is the ideal operating logic of a truly Automatic Generator.

The term "really" is used as a duty, since it tends to (even among industry operators) confuse an automatic generator set with a generating set that can "be started" through a clean contact operated by a separate control panel .

If you want to explain in the second case the second case, it's like taking the startup contact behind the start button and taking it away to another electric board that can close and open the contact or press and release the button.

Obviously, the above-mentioned generator is by no means automatic and that it needs a further logic framework capable of detecting network presence and commanding the generator startup and shutdown. Apostrophate as an "automatic" generator like this is how to go to the fuel distributor and define an "automatic" petrol pump when you really are to refuel to the car. Reflective: It is a common definition but in fact it is an improper term.

A widespread current of thought argues that the management of the automation rendered separately, and therefore not directly into the generator, can give advantages in terms of system reliability since it can easily replace the ATS frame without having to intervene on the generator set.

Frankly, there are many, too many, reasons to reject this solution, which can only be considered valid in some particular cases. Let's just mention just a few of them:

First of all, it is evident that the situation is reversible, that on one hand it might be advantageous to be able to easily replace the ATS frame without having to intervene on the generator just as well as having a switching board without command logic is equally easy to replace without To intervene on the logic of management.

The first advantage of having a truly automatic generator, which has an automatic control panel directly on the generator, is that it has to do with a less control panel. Yes, because even a manual start-up generator set up for automatic starting with remote start contact will have its engine protection and generator management unit. It is clear that managing a single control unit is a "clean" job in most cases.

A) With an automatic control panel it is easy to have a clear situation of what is happening in the plant and on the generator. It also means that you have the generator and the network data available in one device. For example, we can interpret the load / load overload in the generator set behavior.

B) Sometimes the separate logic ATS is merely a line commutator, therefore it does not identify network problems such as low voltage, phase failure, single-phase voltage, etc.

Problems easily identified by the control panel mounted on board

A generator is automatic when it does it all alone. If it needs external intervention then it is not automatic.

Eventually it would be the "system" as a whole, to be automatic.

An automatic generator set is not just a control unit

If it was enough for a control and management control unit to make a generator automated it would be simpler, but that is not the case.

The automatic generator without a static charger would not be able to function properly because the battery of the accumulators would not be sufficiently charged to guarantee one or more start-up cycles.

The static charger is nothing more than a charger powered by the mains voltage to maintain battery charge even when the generator is switched off.

Preheating is another important element for an automatic generator that is often not taken seriously enough.

The start up of an emergency generator unit takes place by taking all electrical loads in one step. To make a comparison is as if in the mornings in the winter season we ignite the engine of our car and start immediately at full speed, perhaps by climbing.

The preheating, also called hot, is a heat source that is powered by mains voltage, keeps the water contained in the engine coolant, or the lubricating oil contained in the cup at a temperature. Both preheating types have the purpose of keeping the engine warm so that the engine can start up even with particularly low external temperatures and above all it can dispense the maximum power immediately without a pre-heating cycle without load.

That's why automates are born: not a manual generator too easily called automatic by vendors but a real automatic generator I no longer think about it.

THREE-PHASE GENERATORS FOR SINGLE-PHASE LOADS: DISTRIBUTE A LOAD.

Orefice Generators - Copyright 2017

When dimensioning the power of a generator, it is necessary to carefully evaluate the type of power to be supplied.

It's very comon that one has a three-phase generator set and has to supply a single-phase load. How to proceed?

You must have heard that a three-phase generator of Power P = 3 kW can drive a single-phase power load of 1 kW because Pm = P / 3.

This condition is valid for all alternators with Star windings connection and a voltage of 400 V, where to obtain the single-phase voltage of 230 V, we just power the load between a phase and the Star center.

“Single-phase loads powered by a three-phase generating set must be distributed in such a way that, at each phase, no more than the rated current of the generator is running.

Notice how we talk about power but also about current, because it is important to note that some loads at the time of insertion have a higher absorption, or higher currents. It goes without saying that an experienced technician can rely first on an experimental calculation, but then he must measure the electrical loads distributed over the phases with the aid of a measuring instrument.

If you do not have a calibration tool, but you have a Generator branded Orefice with VEOTM control panel , you can easily monitor the absorption directly from the Display.

If you do not have a measuring instrument neither a generator Orefice you will not be able to ascertain the correct distribution of loads between phases.

What if the loads are not properly distributed?

It may happen that the generator will go into distress and that the windings inside the alternator may overheat until they "burn" and interrupt.

To make a comparison, we imagine that electric load is a heavy shopping bag that we carry for hundreds and hundreds of meters with the same arm. We will reach our destination with a tired arm that is more subject to an injury. Dividing the load into two envelopes would not change the work to be done, and perhaps even fatigue, however it would be easier to carry the load to the target avoiding pain and risk.

Unbalanced loads are one of the major breakdown factors in an alternator and consequently in a generator set.

That's not all

An unbalanced load can damage the user connected to it, especially when it is a variable load. An electronic equipment user may not work properly.

That happens especially to Audio Services that hire or purchase a generator to which they then connect their panel without taking care to check how much current they are withdrawing from each phase.

Let's take an example to better explain what can happen:

· Generator with electric power Continuous power of 16 kW; Power factor 0,8; Rated voltage three-phase 400 V.

· Single-phase electrical load to be connected to a total of 8 kW divided as follows:

O Halogen lamps: 5 kW

O Other users with a transformer: 3 kW

Instinctlively the less experienced technician would feel free to connect all the halogen lamps under one stage and the remaining 3 kW under another phase. With this subdivision, considering a current of the halogen lamps that is at least 10 times the nominal current for an average time of 0,12 s, it will not only have problems with the lamps being switched on but will overload the generator for at least 0,12 s will not guarantee voltage and frequency values uitable for feeding the remaining 3 kW with the risk of causing damage to voltage values utside the limits.

STADIUM AND GENERATING SETS: NO ONE SEES THE PENALTY KICK!

During a sport event blackout is something extremely harmful and potentially dangerous.

Last May we were involved in supplying a 1600 kVA generator for a Qatar Stadium.

For the occasion I was able to interface directly with FIFA to get information about the specificities required for the use of a generator during FIFA events.

FIFA introduces the subject in a very clear way:

"The delay or cancellation of an event due to the lack of electrical power is unacceptable."

A careful evaluation of the reliability of the main source is useful to the designer to determine capacity and size of all the backup equipment.

We therefore wanted to analyze FIFA requirements and outline possible solutions, here is the result:

It is FIFA itself who suggested this table.

Practical solutions for a Backup System in a stadium

The first solution represents the main power line disposed in two sources, a preferred and an alternate one (diagram a).

Diagram A

In the second solution both utility services are in use and can optionally be configured as main and reserve with the help of manual or automatic switches. (Diagram b).

Diagram B

In the event of a Network failure, back-up power should start immediately, but there will be a time leg due to the seconds needed to start up the fuel and the load switching and takinf off, therefore, the back-up must consider and include some autonomy while the generator starts up since field lighting, which is typically a high-intensity discharge (HID), once it turns off, it requires several minutes to restart and the broadcasting will be interrupted.

This timing range is covered in a variety of ways, including special generators (rotating UPSs) and Uninterruptable Power supply system (UPS).

FIFA establishes a clear requirement of autonomy regarding the amount of back-up power that should have the capacity to operate for a minimum of three hours during an outage.

A stadium is considered a "high availability" system, or a system that is continuously operating for a long period of time.

The measure of the reliability of a system like that of a stadium can be expressed by referring to an ideal percentage of 100% of the use.

The maximum use percentage of the system called "five nines" or 99,99% means a downtime of only five minutes per year.

During a season, a stadium will definitely experience far more than five minutes of stop for repair and maintenance. However, idle times during an event must be zero for some equipment to avoid any interruption. This would require a power of absolute continuity.

Other equipment could tolerate the startup time of the generator (about ten seconds) and some parts of the stadium could tolerate even more.

Hence, the classification of load types should be considered to determine the amount of capacity and size of the redundant units of back-up generators and the UPS system.

Below we find what might be a breakdown of utilities according to a priority classification:

Security (generator available in 10 seconds)

- fire-fighting pump

- fire alarm and detection system

- smoke ventilation systems

- lifts dedicated to fire prevention

- eventual illumination of medical department

Event and Security (Generator UPS available in less than 60 seconds)

- indoor and outdoor lighting

- special departments (data / telecommunications)

- PBX telephony

- security and access monitoring

- giant video screens

Essential event (generator in less than 90 seconds)

- tables

- control room and control panel

- turnstile monitoring system

- police station

Critical event (UPS and generator, zero idle time)

- event lighting

- game control center

- police control illumination

Each section of the load would involve different transfer, wiring, and distribution systems, and the UPS may be static or rotating but will still require additional back-ups from the generator or a battery pack with at least four hours of autonomy.

The most famous blackout in the world of sporting events

Surfing the web reveals news of singular and sudden blackouts you can not imagine they can happen, each caused by different and more or less unpredictable incidents.

NEW ORLEANS During the second half of Sunday's Super Bowl, lights on half of the Superdome roof suddenly turned off. Internet connections in the press room stopped and lights off. After the sudden interruption, many of the 71.024 viewers began to murmur. The failure of about two minutes was one of the most incredible moments in the history of the Super Bowl.

In 2014 to SAN PAOLO A few minutes from the start of the World Cup's inaugural race between Brazil and Croatia, in the plant vip sector is lacking electricity and a generator is literally burning.

In 2015 in Cagliari During a luxury friendly match between Cagliari and Real Zaragoza, after a few minutes the game is suspended because the two headlamps suddenly go out. The blackout continues until the end of the first half and the referee decides to resume the game even if the lighting is only partial.

In 2016 in Palermo During the match between Palermo and Torino, for a few minutes, due to a blackout, some of the lights at the Barbera Stadium have stopped working. Rosanero fans answered with irony trying to light up the cell phone and they chanted a chorus: "Zamparini pays the light" ...

In 2011 in Padua A high-ranking clash on the Euganean Stadium on the Calcio Serie B between the Padua and Turin captain, started to look fought and enjoyable, but that would have turned out to be a real mockery for the Grenades.

During the second race of the race, unusual extra-sporting events are taking place, affecting the game: the lights of the Euganean race continue to fail, with first partial and then total blackouts. Just during the first of these, partial, comes the grid of Ruopolo's advantage that mocks Coppola's grenade goalkeeper who complains of low visibility.

Turin appealed against Padua who there is a danger of a 25-30. 000 euro.

Former Padua and Turin, Roberto Muzzi declared: "Saturday was a great match as far as it was played. The black-out? These things happen, it can happen. "

In 2017 in the race between Flamengo and Vasco da Gama , A game destined to go to history as one of the most incredible. During the race a Blackout left the stadium lit up exclusively by the fans' smartphone lights on the stairs.

Surely in all above mentioned cases more than anyone has generated beyond the obvious economic losses a serious image damage that does not erase certain paying money.

How important is a generator in a stadium?

The answer to this question is "five nine".

Rather the right question would be how much the security and structure manager is willing to risk? What's more, how much is the Calcio team playing matches against you?

Anyone who is not willing to risk turns to a specialized company and is concerned about having the best backup system possible.

We can clearly say that in a structure such as the Juventus Stadium (Allianz Sadium) the precautions taken in this regard are definitely higher than those adopted at other stages where we are often relied on generators to use Shipyard, installed as if there was no tomorrow And perpetually in derogation to something.

It smiles like the unsuccessful generators with obsolete technology, which requires an operator to go directly to the generator to check fuel levels and operational status, while the rest of the world using up-to-date technology is sitting In a steering cabin to handle everything comfortably from a terminal.

It's as if to see if there's still fuel in the car you need to get out of the car and personally test the level in proximity through the charging cap!

Who knows how many times we hear the choir from the Curve

Or some of the hopeless romantic presidents like to see the stadium lit by the fans' cell phones.

Power Generator installed at Alessandria Stadium (Italy).

POWER GENERATOR DOCUMENTS: NEVER WITHOUT!

Generators, whether in emergency or in continuous operation, must necessarily be equipped with documents that permit their use, installation and identification.

What are the documents that should be provided, be it a new generator or a second-generation generator?

In EU countries having a generator without documents is like having a serious problem!

re, dell'alternatore e degli altri componenti del gruppo.

Installation, Operation, Maintenance Manual.

The manufacturer for each machine produced gives a user manual and maintenance that allows the use of the product in a correct and safe way.

The manual is that document (paper or digital) that each operator should read before installing or in any case before using the generator set.

Engine, Alternator, and Other Component Manuals.

It is not essential to have a specific manual for each generator component, except for specific cases. Generator generator usually provides the engine and alternator operating manual.

Manufacturers of diesel engine generators distinguish the manuals in different types, such as the user from the OEM or the workshop manual.

Single-functional and functional diagrams of the control panel.

Together with manuals and other documents, the connection diagram for power conductors and control and control logic (especially in the case of automatic generating sets) is always provided.

It is good practice in the case of purchasing a generator that is used, check that the components and electrical connections are faithfully in line with the manufacturer's drawings. This is to safeguard the unhealthy purchase of tamper-evident machines and therefore no longer in compliance.

Assembly and installation drawings.

The obligation to supply designs of the generating set is defined in the contractual terms. An assembly diagram or a definite design is also known as "as build".

Documentation of any tests carried out.

A capitalized "C" builder performs functional testing and is responsible for all generating sets produced while others perform sample testing to limit production costs that inevitably affect the cost of the product.

Factory testing is a guarantee for the buyer because it minimizes the possibility of failure at commissioning.

In an optimum and real-time quality management system, testing allows any non-compliance to be handled before it can be transmitted to the final customer.

There is no obligation to provide the document certifying the generator's working test, which in any case is a part document.

It is important to distinguish the Test Report from the Test Certificate. The first can be provided free of charge upon request, while for the second one may be provided for a fee.

List of recommended replacement parts for commissioning.

It is necessary to dispose of a myth concerning the parts needed for commissioning: in 90% of cases there are no "necessary" parts for commissioning a generator. In the remaining 10%, these are consumable or specific parts for a particular application.

Warranty certificate.

A generator has a manufacturer's minimum guarantee of 12 months. The warranty certificate is required for the activation of the warranty, since once it is compiled and returned by PEC or recommended, it is a certain date of activation of the guarantee and allows the manufacturer to activate the guarantees of the various components.

Activating late warranty may be a problem, as most manufacturers set a maximum time limit between the delivery of the generator and its activation.

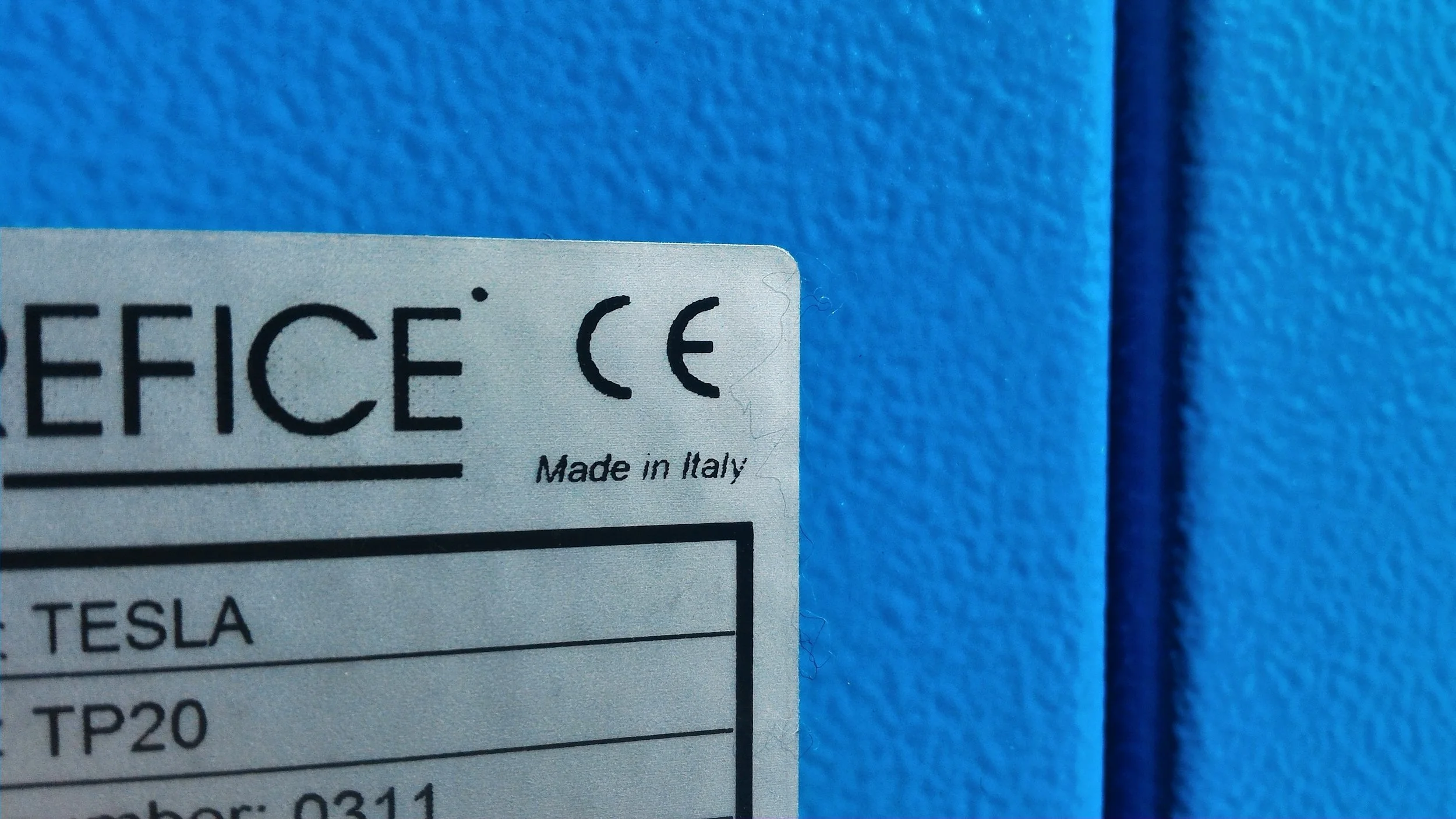

Certificate of conformity.

The purpose of the certificate of conformity is to ensure the free movement of goods within the European Union.

The document is always mandatory, and it is important to clarify some points:

A) Must be supplied in conjunction with the generator set. He must accompany the generator throughout his life.

(B) If the generator is produced outside the EU, the certificate of conformity must be issued by a Community entity, so if you decide to buy a product made in China (for example) then it is good to make sure that the importer has provided To issue the certificate.

(C) The importer entering the Community market shall be solely responsible for the marking and the relevant document.

By doing so, we see the data that must contain a certificate of conformity.

The EC declaration of conformity must contain the following elements:

- the name and address of the manufacturer or his authorized representative established within the Community;

- the name and address of the person holding the technical documentation;

- description of the equipment;

- the conformity assessment procedure followed and, where applicable, the name and address of the notified body which carried it out;

- sound power level guaranteed for the equipment;

- referral to this directive;

- declaration of conformity with the requirements of this directive;

- where applicable, the declaration of conformity and the other community directives applied;

- the place and date of the declaration;

- details of the person empowered to sign the legally binding declaration for the manufacturer or his authorized representative established within the Community.

UGANDA: PHOTOVOLTAIC + TF80 GENERATOR + BATTERY STORAGE.

The generator TF80 is operating in Uganda near Lake Victoria.

It is a Generator successfully integrated into a modern power plant operating in Island mode with the purpose of supporting the storage system connected to a photovoltaic park with more than 800 panels.

The plant is equipped with an "Energy Management System". An advanced energy management system between the various components, and a "Battery Management System", that is, an intelligent battery management system.

The plant provides electricity to over 500 domestic and commercial users, enabling them to have a continuous service of lighting and power supply to various electrical devices for domestic and commercial purposes, such as mills and ice machines, supporting therefore the fragile local economy based almost exclusively on fishing. The use of electricity is handled via a cellular prepaid system, and is monitored through individual smart meters connected to each other as well as remotely.

“I work with a Company that has already purchased the TF80...it is reassuring to know that Orefice support is very responsive...”

How does this generation plant act in Island mode operation and what is the generator for?

This plant bears the distinction of being placed in a context where the power grid does not exist, so all the produced energy is consumed by the users or stored in a Vanadium accumulator battery.

The generator unit comes into operation only when maintenance is performed on the storage and / or the production part, but also in case of excessive power demand for the plant itself.

Are there any other similar power plants?

In the past we have provided generators for similar applications with different powers, starting from 2 kW with generator 24 VDC or 48 VDC, all automated to start the generator automatically when the charge of the batteries is low.

All these applications, regardless of power, have in common pursuit of energy continuity, which is always the basis of our solutions.

HOW FAR ARE YOU WILLING TO RISK? YOUR HOME IS ON THE LINE WITHOUT ELECTRICITY.

Rain comes. If you do not have a generator you are in danger.

In Italy, in September, October and November every year is the same story: The rain expected for an entire season falls in a few hours. The consequences can be devastating and vary depending on how much you are prepared for the extreme event.

How frustrating it is when you lose valuable goods and sometimes a lifetime of memories.

Being prepared for such an event means to be equipped with systems and facilities capable of preventing the accumulation of rainwater. A common example is water lift pumps, usually placed in basements and underground rooms, with the purpose of preventing flooding from rainwater or worse, of sewage seepage infiltrations. Being mainly submerged pumps, their functionning is closely related to the presence of electricity from the grid or from auxiliary sources such as generating sets.

Owning an emergency drainage system for rainwater and not having a generator set is as useless as preparing for a long and important car trip without taking care to fill the fuel before leaving. What a feeling will it be when everything does not work? Anger and frustration will be double.

What is the relevance of a flood or flood and the lack of electricity? It is simple: when there are atmospheric events that interest entire cities or regions, it concern all the infrastructures, including the electrical ones. In exceptional cases it may be the same network operator to establish the disconnection of an entire area from the rest of the network.

The moral is that without electricity electric pumps will not work and you are in danger.

Recently a Hurricane has devastated the Caribbean Sea and then crashed against Miami, USA, leaving millions of people in the dark for many days.

Only those with proper generating sets and high quality fuel loading facilities could face the emergency. By looking at the Social Network images of those who "thanked" their generating sets for the great work done during the emergency, I noticed that everyone set up images of professional generators. In other words, the most striking success stories were possible with really good generators and not the ones that you can get for 149,00 Euros at the mall.

In the picture below, just to give an idea of he difference, you can see on the left a true generator suitable for emergency use while on the right a toy where nothing is funny about it.

Beware, they both have the same power !!

In one of the next articles, we will explore the issue of the best generating set for housing, thus we will explain the technical characteristics of a generator set for the safety of your loved ones and your properties.

Meanwhile, let's try to understand schematically the difference between a generator suitable for operation in emergency conditions and one not suitable for this purpose.

Dimensioning the generator set in accordance with the electric pump or vice versa?

Anything to do with sizing would deserve a separate article, however, a guideline can be outlined to approximately define a power.

First, it is useful to determine which loads to supply, thus, to decide whether to connect the generator to the electric pump or to the entire building including the rainwater lift system.

Choosing to supply an entire building will determine the nature of the loads, the priority and the timing.

Nature of loads : Single-phase or three-phase electrical loads.

Priority: A priority electrical load is such when it comes to an important device. Example: A refrigerator, video surveillance, water drainage.

Timing : Not all electrical loads work at the same time, so the required electrical power may not match the sum of all detected loads.

Regarding power, there are no great deals unless the attention to not dimension the generator at 100% of the load. (A 5 kW electric load should not be powered with a 5 kW generator.

"Sizing" is not just the experimental calculation of the power involved, but it is also the choice of fuel tank capacity that affects the amount of hours the generator can remain in operation.

Placement of the generator:

you need to find the best position of the generator set. If you plan to mount your home-based generator in the basement, or hidden in the sight so that noise cannot disturb, you're starting off on the wrong foot.

If you do not want to hear the noise during the generator motion, you have to install a soundproofing unit (see previous article). Also, choose a generator that is aesthetically up to the environment in which it will be positioned.

Get advice from a professional about where and how to place your home-saving generator.

You'll do a safe and productive job and you'llthank yourself for being far-sighted.

EMERGENCY GENERATOR AT THE HOTEL: WHY YOU SHOULDN'T UNDERESTIMATE IT.

"We stayed in this residence a few days ago for new year's day, a bleckout from 9.30pm up to 04.00AM without any informations from the Hotel Stuff. Obviously, no way about a refound...”

[The Hotel response]

"Dear. Mr Matteo, we are sorry for the discomfort caused by the lack of electricity during the hours you mentioned but, as communicated to all customers, the problem was caused by a failure in the electric cabin of Enel and our staff Maintenance, always present until restoration, was not authorized to intervene. "

If you don't want to justify yourself to your customersas a kid with your customers for something you don't even have to be blamed for, you absolutely should read this article ...

In the modern era, where even the most complex operation is carried out using a smartphone, telling a customer that the fault comes from your network operator sounds ridiculous.

How would you like it if the restaurant owner told you that your Carbonara Spaghetti will never come to your table because "those of the gas" did not bring a loaded gas cylinder?

You can not bounce on the Customer a problem that is exclusively yours.

Emergency Generator at the Hotel: Why you shouldn't underestimate it.

Have you ever tried to keep your eyes closed for a few minutes? Just to test your other senses and maybe orient yourself in a room or a premise. Some of us wake up at night, get out of bed and drink a glass of water without opening the eyes not even for a minute.

My grandfather, though he missed sight as a child, used to remember by heart most of the electrical wires of an electric motor, and was even able to tell others how to connect. Even today, talking to him, I wonder how he did it! I hardly remember what I ate yesterday.

One thing is for sure, though: staying in the dark without seeing anything is difficult. Every operation becomes complicated and you feel a very intense sense of insecurity , so that reopening the eyes, makes you feel like a great relief.

Now, however, we try to make the situation more complicated by the fact that more people inside the same room close their eyes and have to get inside it without hurting themselves.

I think it's definitely complicated, do not you find it?

If you turned off the light, were you? In this case you have no reasons for staresereno.

Should any of those who are in the dark get harmed? No one would want to be in your place.

Maybe you will not believe it but this is what can happen in a hotel when electricity is lost and everything goes out: lights, elevators, hoists, computers, telephone switchboards, video surveillance, home automation, etc etc A large number of people (including you) find themselves closed-minded to have to move hoping they will not do harm and above all not hurt someone.

Maybe you're thinking I'm just pulling water out of my mill, and here you live blackouts and emergency generators during blackout, but you're wrong.

In fact, the solution to the situation I have imagined before is not to have an Emergency Generator in the Hotel, but something more: " Possessing an emergency generator that is really efficient ".

Between having an emergency generator and having one working there is a big difference, like that between launching an airplane with a parachute or throwing a rucksack.

Most of the hotels with a couple of stars and a quality-oriented property feature an emergency generator, but only 3 accommodation on 10 has one that actually works.

Why? It's simple: they do not do the proper maintenance!

When a computer does not work, or when an air conditioner is failing, the facilities quickly resolve the problem, and when it comes to emergency generator sets it seems there is always time available.

If you are a maintainer and you are wiping your nose, I can assure you that you are misunderstood what I have written. I know you are maintenance to the generator, but we both know that you sometimes have some sometimes structural and / or temporal limits for which you certainly have no fault. (You probably often find yourself doing more than you would have to do).

We can say, if I were a top-of-the-line generator, the generator would be the most efficient machine in the facility and it would not be in the least economic and image loss.

I remember the matches of Soccer where the goalkeeper who missed the last minute and missed in turn came to the door. It happens then that at the end of the game there is always the "phenomenon" that pulls the sums with other comrades on how many goals the team lost my fault while I was in the door.

Now I say, but in my opinion if I was a "good goalkeeper", would I ever play soccer with you ?!

That is why it must be objective: The regular maintainer, though good and prepared, can make some nice parade, but to save a penalty it will take a real Goalkeeper!

Security: Protect yourself

Bullets, burnt, crushed, suffocated, mutilated: Generating sets may die.

Being aware of those who are at risk while starting a generating set could make the difference between a live and a deadman maintainer.

Speaking of security at the hotel or in any accommodation facility, restaurant, bar, etc, we refer mainly to two figures, that of the client is that of the employee in the structure.

Both figures must be protected in the same way but with different systems and instruments since it is clear that the level of information you can give to the customer is not comparable to what you have to give to your staff.

In order to protect you, you have to protect it, so in practice you have to give evidence of how you have provided specific training on the generation of the generator and how this has been maintained efficiently through regular maintenance activities.

Costs: how to handle them

Specific strategies can be adopted to optimize the costs of managing a generator.

The first thing to avoid is that you do not handle the maintenance regularly. Statistically, a maintenance-free generator does not work right at the moment it has to work.

An intelligent way of managing costs is also to plan the most important maintenance interventions during low attendance periods, allowing scheduled rematches and functional tests, avoiding having to require night or week breaks at higher rates.

Safely manage a generator failure at the Hotel

For your safety and that of your collaborators, I ask you to avoid improvised and precarious solutions that may turn away from you. It's better a blackout than a serious accident.

As soon as you notice a blackout that is not readily contained by the emergency generator, you can proceed by following these three simple steps:

1. Find out the magnitude of the blackout. You have to determine whether this is a fault in your facility or a failure affecting a wider area served by the electric operator.

2. Make sure there are no Guests inside any elevators, and then put them out of service.

3. Only after you have made the previous steps you can collect the ignition information and contact the service center. When contacting the service center, keep the generator, engine and alternator nameplate data available.

If I read this article is a Hotel Manager or a maintainer, I can prophesize with certainty that in the event of blackout and failure of the generator, both will rush in front of the generator to try to figure out what is happening.

I know very well what happens in these cases, so I thought about giving you a gift: "A cover for the main breakdowns of the generator". It is a poster we provide to all Hotels that enter into a maintenance contract with us. It is very useful in case of failure because it allows you to understand how to operate and contact us aware of what is the information we need.

Our "hotels" usually expose them outside the technical premises, or they keep a copy in the office at hand. Often they have solved many problems autonomously without cost of intervention.

HOW TO CHOOSE A USED GENERATOR. TIPS TO BUY A USED GENERATOR THAT WORKS PROPERLY.

How much a used generator is worth? What are the most important checks to do? Find out how to choose a used generator even if you do not have special skills in the mechanical or electrical sector!

(Video at the bottom of the page)

If to buy a generator we have to avoid only 6 mistakes ( so to speak), when buying a used generator, the situation gets complicated and it is crucial to be able to select a generator without ending up on something that can reveal a bad purchase.

The main concern is not the fact that someone before us used the generator, but rather is it the fact of not knowing if he used it with scrupulous and careful attention.

The ideal thing is to get along with an expert, a professional who knows what to look at and can distinguish a deal from a mass of problems

It's natural though that if you're reading this article you probably do not want or cannot get a hand lended from anyone, so let's go straight away with the information you need to not fall into a wrong choice.

Identifying the Generating Set: Is It Really It? Has it been tampered with?

A key step before proceeding with any test is to identify the generator unit by verifying that the data on the plate conforms to the documents submitted by the vendor.

Verify the identity of the generator, verify that no tampering has been occurred.

We are talking about changes that compromise its operation. Let's take some examples:

The emergency stop was inhibited; The shutdown system has been changed; the EC caps have been removed from the engine; the switch has been replaced with one having different characteristics, the operating logic has been changed, changes have been made to the chassis or bonnet, etc etc.

Without documents it's never a deal.

We will often make similarities with cars. An Unlocked Generator Set and like a car without a circulation card.

Some people make the mistake of thinking that a generator can later be equipped with the documents needed for its use, but this can never be taken for granted.

Issuing documents, especially when it comes to products from other manufacturers, is an expensive operation that many tend to underestimate.

Actually issuing documents for a machine we did not design and we did not build is a great responsibility towards the user and to those who designed i considering the main risks and residual risks.

It is crucial when you look at a used generator to ask the owner to show you the generator's documents.

These documents are the certificate of conformity, user manual, maintenance manual. Sometimes the user manual and the maintenance manual are in the same brochure. If you want to deepen the topic, we have dealt with this topic in another article dedicated to generic set documents.

Drawings, technical sheets, and other material are useful and very important elements but are not indispensable, and above all they are not mandatory for doing business with a generator set.

Reissuing the documents due to the loss of the originals may be required through the intervention of the original manufacturer.

Reconfirming the compliance of a generating set binds the certifier to produce a complete technical file and a residual risk analysis.

In addition to being compliant with the regulations in force, the documents must comply with the identification plate on the generator set. The plate must bear the CE marking, the power of the generator, the generator model, reference standard, and other technical data to identify the machine and its operation.

A generator set without documents could not be sold, and in any case could not be installed and used.

A generator with a certificate of conformity can be installed, but cannot be used if the user manual is not present on site.

The recertification of a generating set provides for the availability of documents useful for issuing a new certificate. They are the documents relating to the main components of the generator, for example the diesel or gasoline engine, the alternator and other components of the electric board.

Hours to work, year of production, but not only.

Working hours are important but must be evaluated taking into account the context in which they worked.

Let's take an example to understand the concept: Would you prefer a used car that has 100.000 km mostly on the highway or one that has run 100.000 km on a mixed path?

Is it better having a generator that worked a few meters from the sea , a generator that worked in a sand quarry, or a generator that was in emergency service at the mall? Salt, sand, or the quietness of a technical room in the underground of a building?

In the case of the generator, we must first evaluate whether the operating hours have been totalled in a continuous or emergency mode, then try to understand in which environment it has worked.

The engine, this is what you must never neglect.

Take a look at the engine .

There should not be excuting fluids. Check the belt that is usually well visible.

Smokiness

During a cold start a black smoke or a white smoke may be normal.

Black smoke: In the case of black smoke during operation, there is probably an excessive consumption of oil , from the dirty oil filter, or the presence of exhausted engine oil.

White Smoke : The emission of white smoke during operation requires deeper checks because it can mean a lot of things. It could be caused by a low amount of coolant, by the presence of water in the diesel, an injection delay, a cracked piston, the head gasket, etc.

Please note that during operation at load, the smoke increases considerably.

Dampers

Check the status of the anti-vibration pads: with the engine off and cold push the coupled alternator motor to one side. The engine must move and return to position without residual oscillations.

Do not neglect this detail, it is a matter that only experts control. A generator that is proposed as "equal to the new" will have all the kit of anti-vibration in excellent condition.

Cooling Radiator

Open the coolant cap: there must be no oily residue, which indicates a possible fall in the head seal.

You could repeat the control before starting and after the test run. Be careful during these checks, the liquid temperature is burning.

Noise Frequency and Voltage under load

Consider when the load is switched on, if the motor reacts promptly by returningvoltage and frequency to nominal ones.

Quality and Pressure of Lubricating Oil.

When the engine is cold, check the oil level, and with a cloth score if there is a possible presence of solid residues, a symptom of engine wear.

When th engine is hot, open the oil filler cap, there may be a natural outbreak of hot vapors but there must not be an oil spill.

Connections and wiring

Check that the system is in order and that there are no traces of burnt or rigid or deteriorated conductors.

Security systems

The generator must automatically switch off for low oil pressure, high coolant temperature.

Try also the emergency stop button. (Required). Shutting down should take place within seconds.

Operating test .

If you are purchasing an automatic generator, simulate the lack of network by selecting "Automatic" mode from the control panel. The generator must start the engine in 5 few seconds.

It may not be enough to start the engine and check that the voltage is at the nominal level. The best test is the load, at least 50% of the load that the generator can withstand. A charge test could be paid as it involves a technician and there is a natural fuel consumption.

The Alternator, fundamental but never verified.

The alternator is one of the most neglected components in the generator, although it is also one of the most expensive after the first engine.

More than half the problems experienced by a user who has a used generator is to find surprises on the alternator.

In fact, on the 90% of the generating sets only engine maintenance is often performed and often not complete, reducing the replacement of filters and lubricating oils.

A regularly maintained and revised alternator by a qualified and experienced personnel has relatively high life expectancy.

One of the reasons why the alternator is never verified by the user who intends to buy a generator set is the general lack of expertise in understanding the aspects to be verified in the alternator

It is important not to ignore the fact that the alternator is made up of rotating parts that are subject to vibration and mechanical stress which over time can create wear and then fail to adequately repair them.

Few people know that the mono-support alternator, equipped with a single headset bearing, has a well defined maintenance plan that provides for replacing or lubricating the stand regularly.

The control panel.

The control panel is essentially an electronic component. Make sure it is the original one assembled by the manufacturer of the generator, if it's not the case, ask for information on the kind of intervention performed.

Remember that if the control panel is replaced on a generator set without the necessary adjustments, the operating hours start from zero.

Clear signals but almost (all) ignore it.

It's not all. There are signs that only a watchful eye can notice. In fact all that we have explained in this article is 50% of what you should know, a share of all respect that will allow you to avoid throwing away your money.

From whom to buy a generator set used ?

Used generating sets can be found by private vendors who have ceased their activity, from specialized dealers and dealers.

The suggestion is always to turn to a builder first because he will not take the risk to put into service used machines that could bother him and make him bad publicity.

Resellers and small craftsmen are an unknown, in our region, for example, there are companies that retrieve scrap of years 80 and restructure without a criterion and without producing really valid documents.

Manufacturers or their dealers, on the other hand, often take over generating units that have not accumulated a large number of hours and sell them at competitive prices.

Used yes

Watch the Video with Tips to Purchase a Used Generator That Works. What to check, what to ask, what are the most important things and all you need to be sure that the use you've identified is actually what you need.

Watch the video with tips for buying a used generator that works. What to check, what to ask, what are the most important things and everything you need to make sure that the used one you have identified is actually the one that is right for you.

HERE ARE 6 ERRORS TO AVOID WHEN BUYING A GENERATOR!

Get your money. Hand it to the generator seller, the "Generators Monger", and your new generator will be delivered to you.

Easy, isn't it?

For some people, buying a generator set was such an experience, so simple before but so hard afterwards, when you find that you bought the wrong one.

I could assure you that by buying a Generator Orefice Generators Bla bla bla bla bla bla bla bla bla ..., Customer orientation, bla bla bla, quality, etc etc, but I want to do something more to be out of the 6 mistakes that you should not Absolutely do when you buy a generator set. I would like to tell you that you are on the other side of the bench.

Whoever purchases a generator can be a final user, the one who will actually use the product, or a reseller who may install it or put it into service. For both figures we have important information, so do not give up and come to the end of the article.

If you really want to buy a piece of junk, well, at least you will do it fully aware and informed.

1. You don't know why you need to buy a generator.

Trivial but so important.

You can not buy a generator without knowing what kind of application you intend to run. Before contacting a manufacturer or installer / retailer, get yourself together and collect these data:

· Do you want a generator that starts when the power supply is missing or do you want to start it manually?

· How many hours a day will you use the generator?

· What kind of equipment would you like to supply with the generator?

· Do you know the power and voltage of the equipment to connect?

To be clear, even in the absence of the information above, many will be able to formulate a bid, but it will be an economic proposal and not the "solution." If you ask for an offer without providing these details, it will be like deciding on the place to go for a holiday by spinning a globe and picking a point: you have a huge chance to end up in the Pacific Ocean.

2. Thinking the only difference is the power.

The first mistake, which is also the most widespread, is to believe that generators are all equal and that the only difference lies in their power.

Well first you have to completely reset this conviction which will lead you at best to spend more money, and at worse to buy something you do not need and you will not be able to use.

If I offer you a trip asking you to choose whether to travel driving a Lamborghini Aventador or on a dromedary hump, what would you choose?

Have you chosen Lamborghini?

Can I make you change idea if I tell you that the proposed trip must cross a desert of sand dunes? I think so! Although you are probably not an expert on Lamborghini and Dromedaries, you will surely reevaluate your choice because you understand that there are important differences in the result, though both are very different means of transport. You also know that the most suitable product is related to nothing else but your need.

....

When choosing a generator for you or your customers, do not evaluate only the power.

If the generator is for you or your company, consider at least these three elements:

· Maintenance intervals and related costs.

· The presence of all the equipment that allows it to operate.

· The brand of the engine and the presence of a brand distributor in your country.

If the generator is for your customer, you may think that the previous points do not concern you, but always remember that the customer is yours! Whatever you propose, any product you install will remain your Customer, maybe you will not say "thank you" when you have provided a working product, but be sure it will make a nice registered letter when the product you provided will not be what you expected or Even will not conform to the specifications.

So pay close attention to what you bring to your Clients :

· Consider the application and the power you need.

· Consider installation costs carefully.

· Please note that you may have to provide some kind of assistance during the warranty period.

3. Look but don't read.

We have to realize that 90% of people who want to buy a generator (this is not only for generators) do not know how to read a quote, especially when it contains a large amount of technical and operating specifications. With this we are not insinuating that 90% of people do not understand anything about generating sets, but reading an offer is often misunderstood, and the part where equipements are mentioned is neglected

Magic tricks are not a rare thing, it's a widespread vice, with offers for supplying generator sets without fuel tank, without main switch, no silencers, no starter batteries, no liquids Of the first plant, just to name a few.

There is nothing wrong with proposing a generator without one or more of the above elements, provided that this difference is technically considered first and then economically.

4. Go buy tomatoes back with the Onions

"The engineer told me that I need a 10 kW generator in continuous duty, three-phase with electronic xxxx engine 1500 rpm".

Then it happens that you meet the pitchman that does not distinguish a diesel engine from a gasoline engine and come home with a 10 kW single-phase generator withengine at 3000 rpm .

It is not an extreme example, it is a real case, a common story among many who are lost in the purchase of a generator, for inexperience, for the belief of making a deal, lack of competence, and so on and so forth .

Have you ever been to go shopping and buy onions just because you did not find the tomatoes?

I really do not think so! So why buying an "inappropriate" generator just because you did not find the generator you were looking for?

I propose you a logical patterns to follow in order to better evaluate your choice.

Gasoline engine generator - Only for "manual" applications, never for automatic applications.

Generator with Diesel Engine at 3000 rpm - Only for non-continuous applications, max 3 / 4 hours per day or with a break of at least 2 hours between each work cycle.

Generator with Diesel engine at 1500 rpm - All applications with continuous and intensive use.

Generator set with Diesel engine electronically controlled - For applications where you have sensitive devices.

5. Buy a "base" product convinced that you can modify it.

The unsound idea usually arises for budget reasons when you can not afford anything but want it the same, so invent a project that allows you first to buy a basic product and then turn into a McGiver trying to modify the generator.

I have to disappoint you: in the vast majority of cases you can not do it. You can not modify an EC marking machine without proceeding according to the standards.

Do you want to buy a generator with manual start and then turn it into automatic? You will spend more and you will have to certify it.

Would you like to buy a generic open cabinet without cabin and then build a "home" to fit it? You will spend more, also the "home" will be compared to a technical room, so it will have to comply with some specific features.

The advice is to make a measured but correct investment, buying everything you need and all the necessary options directly mounted at the factory.

6. I will never use it

"I will never use it." We often hear this phrase from many Customers. They are convinced that they will install the generator and that this will never come into operation, because "so much current is never missing".

You know the biker who did not put the Helmet because "It's okay, I don't fall that easy

This generator theory that will never come into operation has been carried on by some manufacturers who wanted to market products with low-cost Chinese engines and alternators. Commercially, it perhaps, makes sense, but to technically justify such a stupid choice they invented the story of the generator that will never turn on.

If you are convinced that the generator will never start, then do not buy it!

Here is the full video where we talk about the mistakes to avoid when purchasing a generator.

If you like Video, subscribe to our Youtube channel to stay up to date on all of the upcoming videos.

....

The difference between a Generator with engine 3000rpm and 1500rpm

What's the difference between a generator set 3000 rpm and 1500 rpm?

A generating set per definition is a combination of an internal combustion engine and electric generator.

The most common engines are those Diesel and Petrol engines with 1500 rpm or 3000 rpm, means revolutions per minute. (The engine speed can also be lower than 1500).

So what is the difference between a generator 3000 rpm and 1500 rpm one?

Technically we have already answered: one engine in one minute executes 3000 rotations, while the other in the same minute runs 1500, or half. It means, in other words, that if a speedometer measure the number of turns to the shaft of one and the other, we will get either 2 revolutions and 3 revs respectively.

This difference leads to obvious Consequences that should be known when buying and while using a generator:

Life Expectancy

An engine with 3000 rpm has a lower wait than the engine 1500 rpm. This is due to the strain difference to which it is subjected. Think of a car traveling at 80 km / h in the third gear and a car traveling at 80 km / h in fifth gear, both reaching the same speed but with a different mechanical stress.

If we want to give numbers, we can say that a generator set with diesel engine 3000 rpm reached 2500 hours of operation may need a partial or total review, while for a diesel engine 1500 rpm this may be necessary after The 10.000 hours of operation. (Indicative values).

Operating limits

Some say 3 hours, more 4 hours, or 6 hours of continuous operation.

A 3000 rev / min engine has a limit on running time, usually after a few hours of operation it would turn off to allow it to cool down and check the levels. This does not mean that it is forbidden to use it h24, but that continuous use is not appropriate. A high number of laps, for a prolonged time, is not ideal for a diesel engine.

Weight and Dimensions

The engine at 3000 rpm with equal power has smaller dimensions and weight than the 1500 rpm since it has different technical characteristics to reach the rated power. Usually these are air-cooled mono and two-cylinder engines.

....

Running Costs

The cost of the 3000rpm engine is lower and, consequently the generator’s cost too, and even the running cost is different: usually an engine working under stress tends to accumulate over time in number of failures and maintenance higher than the average.

The noise

The noise of a motor generator at 3000 rpm is usually higher, and even when it has an acoustic pressure similar to that of its half brother with engine 1500 rpm, the sound frequency is more annoying in the case of the motor 3000 rpm.

Taking these aspect into consideration you will have a better idea to select and use Your generator.

When you SHOULDN'T buy a generating set...

When you SHOULDN'T buy a generating set

When estimating "how many" … is important.

This is not a title made to draw your attention. In this article I intend to explain you from my perspective what are the cases in which you absolutely shouldn’t buy a generating even if this could work against my own interests.

The difference between an amateur and a professional is that the first will tell you anything to sell, the latter will tell you the truth even when it is inconvenient and could postpone the sale or even lose it.