The automatic generator is a generator equipped with a Diesel engine that can boot up in the absence of electricity,

We specify "Diesel engine" since a gasoline engine generator can be automatic but it is extremely unreliable because the petrol engine does not have the same startup speed after long stop periods as automatic generator sets usually do.

Automatic generator is a generator that operates according to the following logic:

1. It should identify grid failures or anomalies in network parameters

2. Start and control the Diesel

3. Pilot the contactors or one or more motorized switches / circuit breakers for the connection of the load

4. Detecting the Return of the Network in the Parameter Triggers

5. Switching for network / network connection

6. Stop the Diesel

7. Return the position of the point 1 ready to repeat the cycle whenever it becomes necessary.

The above descrition is the ideal operating logic of a truly Automatic Generator.

The term "really" is used as a duty, since it tends to (even among industry operators) confuse an automatic generator set with a generating set that can "be started" through a clean contact operated by a separate control panel .

If you want to explain in the second case the second case, it's like taking the startup contact behind the start button and taking it away to another electric board that can close and open the contact or press and release the button.

Obviously, the above-mentioned generator is by no means automatic and that it needs a further logic framework capable of detecting network presence and commanding the generator startup and shutdown. Apostrophate as an "automatic" generator like this is how to go to the fuel distributor and define an "automatic" petrol pump when you really are to refuel to the car. Reflective: It is a common definition but in fact it is an improper term.

A widespread current of thought argues that the management of the automation rendered separately, and therefore not directly into the generator, can give advantages in terms of system reliability since it can easily replace the ATS frame without having to intervene on the generator set.

Frankly, there are many, too many, reasons to reject this solution, which can only be considered valid in some particular cases. Let's just mention just a few of them:

First of all, it is evident that the situation is reversible, that on one hand it might be advantageous to be able to easily replace the ATS frame without having to intervene on the generator just as well as having a switching board without command logic is equally easy to replace without To intervene on the logic of management.

The first advantage of having a truly automatic generator, which has an automatic control panel directly on the generator, is that it has to do with a less control panel. Yes, because even a manual start-up generator set up for automatic starting with remote start contact will have its engine protection and generator management unit. It is clear that managing a single control unit is a "clean" job in most cases.

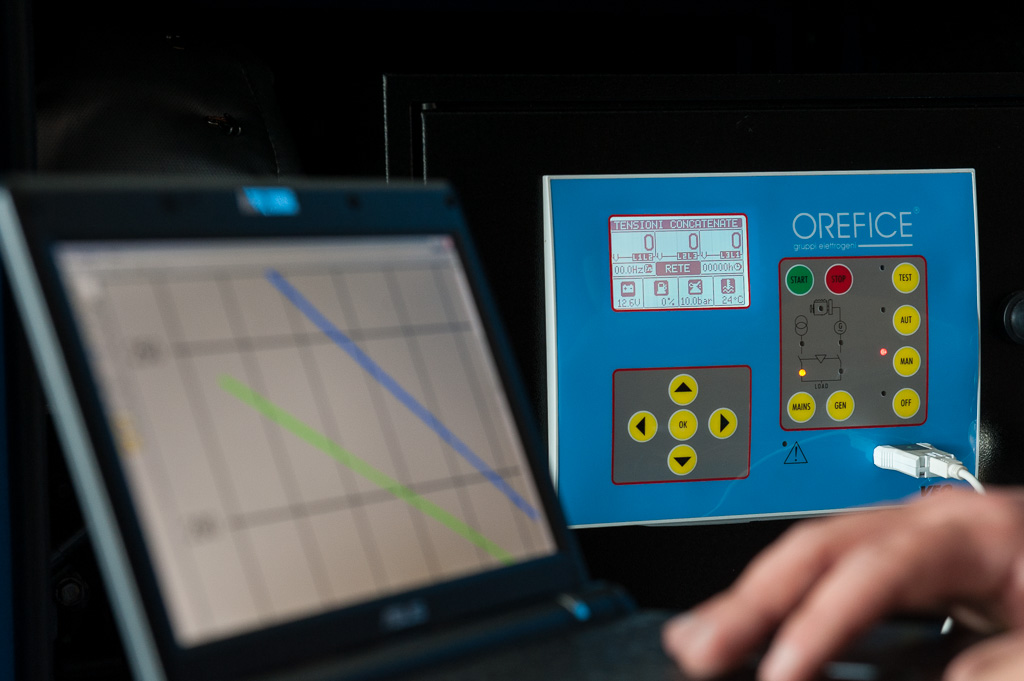

A) With an automatic control panel it is easy to have a clear situation of what is happening in the plant and on the generator. It also means that you have the generator and the network data available in one device. For example, we can interpret the load / load overload in the generator set behavior.

B) Sometimes the separate logic ATS is merely a line commutator, therefore it does not identify network problems such as low voltage, phase failure, single-phase voltage, etc.

Problems easily identified by the control panel mounted on board

A generator is automatic when it does it all alone. If it needs external intervention then it is not automatic.

Eventually it would be the "system" as a whole, to be automatic.

An automatic generator set is not just a control unit

If it was enough for a control and management control unit to make a generator automated it would be simpler, but that is not the case.

The automatic generator without a static charger would not be able to function properly because the battery of the accumulators would not be sufficiently charged to guarantee one or more start-up cycles.

The static charger is nothing more than a charger powered by the mains voltage to maintain battery charge even when the generator is switched off.

Preheating is another important element for an automatic generator that is often not taken seriously enough.

The start up of an emergency generator unit takes place by taking all electrical loads in one step. To make a comparison is as if in the mornings in the winter season we ignite the engine of our car and start immediately at full speed, perhaps by climbing.

The preheating, also called hot, is a heat source that is powered by mains voltage, keeps the water contained in the engine coolant, or the lubricating oil contained in the cup at a temperature. Both preheating types have the purpose of keeping the engine warm so that the engine can start up even with particularly low external temperatures and above all it can dispense the maximum power immediately without a pre-heating cycle without load.

That's why automates are born: not a manual generator too easily called automatic by vendors but a real automatic generator I no longer think about it.